SUND series plastic cup thermoforming machine is applicable for producing various disposable plastic vessels, such as tea cups, yogurt cup, ice cream cups, milk cups, jelly cups, instant noodle bowls, etc, the workable material canbe pp sheet, ps sheet, pet sheet and ABS sheet etc. It can finish producing the product at one time through sheet feeding, heating, stretching, forming and edge cutting.

1 minute to take you understand how thermoforming production line works:

1. Buy plastic granule raw material (pp or ps or pet) ;

2. Feeding plastic granules material into plastic sheet extruder to make plastic sheet roll;

3. Feeding plastic sheet roll to plastic thermoforming machine to make plastic cups or trays;

4. Take the finished plastic cup to cup printer for printing or no need printing;

5. Take the edge trimmings (from thermoforming machine) to the crusher for making recycled chips, mix the recycled chips with the virgin new raw material for use again.

Description:

SUND series plastic cup thermoforming machine is applicable for producing various disposable plastic vessels, such as tea cups, yogurt cup, ice cream cups, milk cups, jelly cups, instant noodle bowls, etc, the workable material canbe pp sheet, ps sheet, pet sheet and ABS sheet etc. It can finish producing the product at one time through sheet feeding, heating, stretching, forming and edge cutting.

Plastic mould:

SUND series plastic mould is custom-made as per customer’s requirements. The customer shall provide the cup/tray/container size, such as cup diameter and cup height, so my mould designer will design the mould accordingly. The mould features high precision, long service life, easy to change the spares.

Finished products samples collection:

Specification:

We have a few models for your option, SUND-660/350 is the basic model, while SUND-750/450 is the luxury model comes with much more forming area and much more production capacity.

Machine Model | SUND- 660/350 | SUND-750/450 |

Sheet Materials | PP.PS.PET.PE.ABS | PP.PS.PET.PE.ABS |

Sheet Width | 500-660mm | 600-750mm |

Sheet Thickness | 0.3-2mm | 0.3-2.5mm |

Max. Forming Area | 680x350mm | 720x450mm |

Max. Forming depth | 140mm (Can be adjust to220mm with request) | 180mm (Can be adjust to220mm with request) |

Forming Pressure | 0.5-0.8Mpa | 0.5-0.8Mpa |

Production capacity | 10-30mould/min | 10-35 mould/min |

Heating Power | 80 Kw | 120 Kw |

Motor Power | 8.5 Kw | 11 K w |

Total Weight | 4.2 ton | 5 ton |

Water Temperature | >30℃ | >30℃ |

Overall Dimensions | 3500x1500x 2200 mm | 4000x1600x 2200 mm |

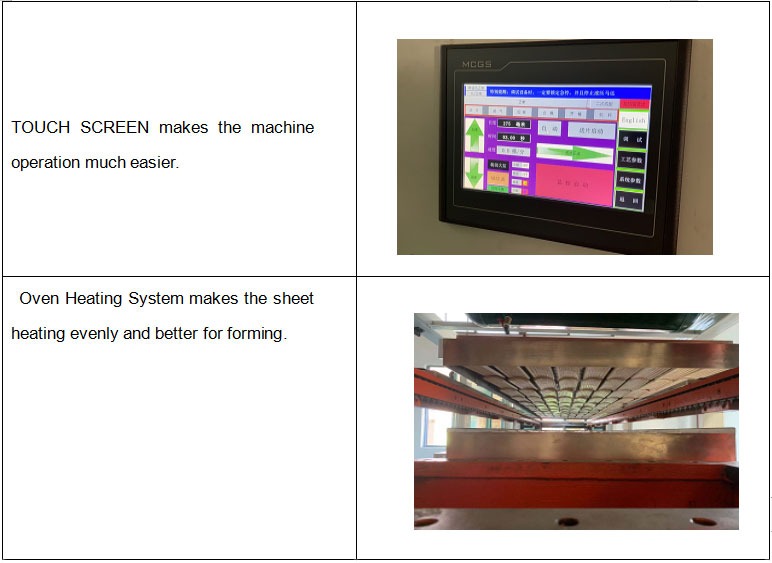

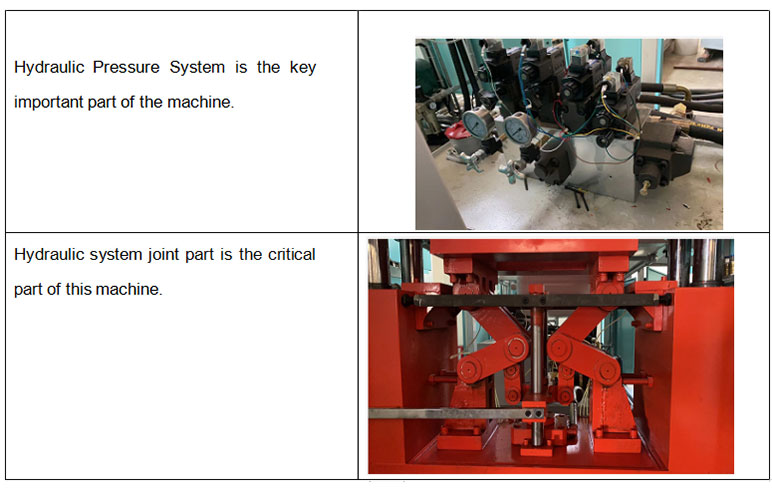

Machine Parts Details:

Machine Delivery:

Contact: Office in Chile: Mr Azarias Vera

Phone: +56936490286

E-mail: azarias.veraverav@sundeep.cn; azarias.veraverav@gmail.com; info@sundeep.cn

Whatsapp:+86 13375778695; +56936490286

Add: Yongguang Industrial Zone, Ruian City, Zhejiang Province, China